Why Choose US

We have always been dedicated to promoting the development of solar street lights.

In modern urban road planning, environmental protection has increasingly become a popular theme. Solar street lights have become the best choice for sustainable development. And now we often see solar street lights in various parks, parking lots, and gas stations. As cities grow, solar lighting plays a key role in shaping a greener, brighter future for the entire nation. For many B2B solar street lamp procurement enterprises, it is very important to understand some of the procurement points for solar street lamps. That's where this guide comes in! From setting clear goals to identifying the right supplier, we meet your needs. Dig deeper and let us show you how to make your ideal solar lighting solution.

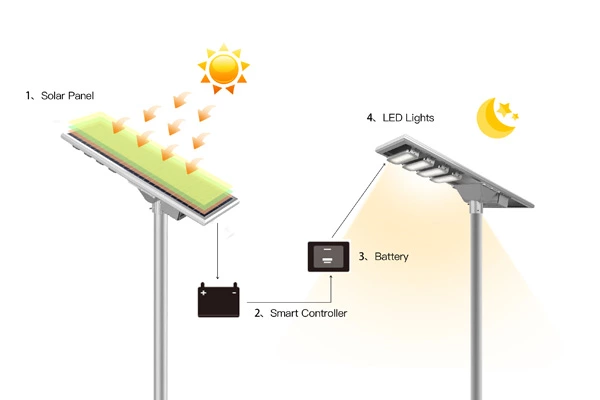

Solar street lights, as the name suggests, harness the power of the sun to illuminate our streets and provide a safe environment for people to walk in. At their core, these lights consist of a solar panel, battery, solar controller, light source, and often a motion sensor. During the day, the solar panel absorbs sunlight, converting it into electricity. This electricity is stored in the battery, ready to power the light source as dusk falls. As night approaches, the stored energy lights up the streets, ensuring consistent illumination, even on cloudy days or during power outages.

Diving deeper, there are various types of solar street lights, each tailored for specific needs. From integrated all-in-one designs to split-type configurations, the choices are vast. In terms of function classification, there are solar induction street lights and ordinary solar street lights. The induction head installed on the solar street lamp can more efficiently control the brightness and lighting timing of the LED light. Understanding the types of solar street lights will help you determine the procurement needs of different buyers. Here I will introduce three mainstream solar street lights for appearance classification. They are: integrated solar street lights, cantilever solar street lights, and split solar street lights.

First, there are the Integrated Solar Street Lights, which are the embodiment of simplicity. As an all-in-one solution, they combine both the LED lights and solar panels into a single unit. Typically, they are priced moderately well given their compact design. Solar panels and batteries will not be very large, and the lighting scene will be limited. With fewer components, maintenance is minimal.

Next up are the cantilever-type solar street lights. These are characterized by a distinct separation between the LED lights and solar panels, with the latter affixed to the LED light poles. It has no space limitations for integration and can be installed with more powerful solar panels. Because solar panels are large and independent, they tend to be more expensive than integrated solar street lights. Maintenance involves periodic checks on the connections between the two separate components.

The other option is split-type solar street lights. The solar panel on top of the split solar street lamp is installed directly on top of the lamp pole, separate from the LED lamp. Depending on the battery, some batteries may need to be buried in the ground. If you're using a lead-acid battery, it needs to be buried in the ground because of its size and weight. They are usually the priciest, given their intricate design and larger components. Technically, they offer robust performance, especially in areas with inconsistent sunlight. Their application is vast, from highways to large public areas. If the battery is buried, it needs to be replaced in 3-5 years.

The quality of solar street lights is a dynamic field. Depending on the material, there are certain key factors that must be prioritized for successful procurement. These factors not only ensure the service life and efficiency of street lamps but also guarantee the best return on investment on a street lamp. When purchasing solar street lights, the first thing that should be considered is the efficiency and quality of the panels, because they are energy collectors. Next are the capacity and material of the battery, ensuring that the light is stable during use. Another material that is also related to stable lighting is lamp beads, which also determine the effectiveness of the light. Due to light pole weight issues, you can choose to buy locally to avoid long-distance shipping costs. This gives you more flexibility when choosing light poles. The durability and manufacturing quality of solar street lights speak volumes about a product's resistance to time and other elements. Finally, we will popularize street lights and more energy-efficient solutions for the use of solar energy. As we delve deeper, each of these factors will unravel, leading businesses to make informed purchasing decisions based on the information they have available.

One of the core components of the solar street lights is a solar panel. The efficiency and quality of solar panels can significantly affect overall performance. Different types of buyers will have different needs in the selection of solar panel materials. If you are an engineering company, you usually choose high-conversion and strong solar panels. They want to ensure that the lighting facilities can be used for a long time and are safe after the completion of the project. Brand customers need to maintain their brand reputation. So they generally prioritize the efficiency and service life of solar panels. Building materials for supermarkets to meet different types of customer needs, from economic to high-end solar street lights, is their procurement scope. Therefore, when some building materials supermarkets purchase solar street lights, they usually consider all types of solar panel materials. Traders are the bridge between the street lamp and the end user, and the end user often pursues the balance between product quality and price. Therefore, traders usually choose more cost-effective products when purchasing. In essence, it is crucial to understand the specific needs of the buyer group when choosing the right solar panel material.

Now let's talk about the key indicators of solar panel performance. The conversion rate of solar panels determines whether or not the solar street lamp is charged efficiently. This is an indicator that quantifies the conversion of sunlight into electricity through the photovoltaic process. If the conversion rate of solar panels is 20%, that means that 20% of the sunlight hitting the solar panels can be converted into usable electricity by the solar panels. The conversion rate of most solar panels hovers between 15% and 22%. However, we need to note that the conversion rate of solar panels does not depend entirely on the material being used. Even though they are the same material, the conversion rate will vary depending on the manufacturer's process or technology.

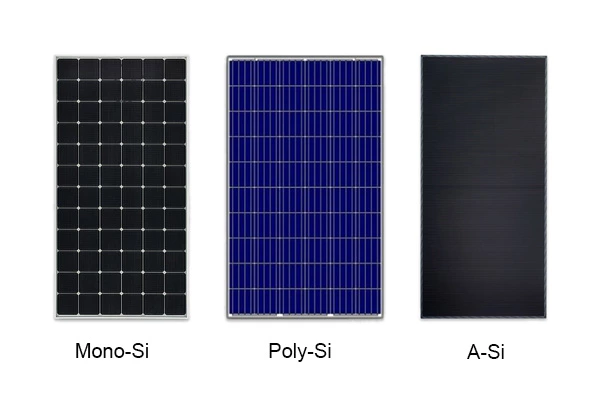

The material in a solar panel is an important factor in determining the conversion rate of solar panels. Right now, the most commonly used materials on the market are crystalline silicon solar panels and thin film solar panels. Crystalline silicon solar panels are divided into monocrystalline silicon and polycrystalline silicon solar panels. These panels have a high photoelectric conversion rate. The photoelectric conversion rate of monocrystalline silicon solar panels ranges from 17% to 22%. Compared with monocrystalline silicon, the crystal structure of polycrystalline silicon is not as ordered, so the photoelectric conversion efficiency is slightly lower than in monocrystalline silicon. The photoelectric conversion rate of polysilicon ranges from 15% to 17%. Thin-film solar panels are made of amorphous silicon. It is relatively thin and suited for more flexible application scenarios. Its photoelectric conversion rate is relatively low, usually in the range of 10%–13%. In terms of cost, the most expensive material is monocrystalline silicon, followed by polysilicon and thin film. There is also an emerging solar cell material currently on the market. Perovskite cells have high conversion efficiency, and the photoelectric conversion rate is usually more than 20%. They are usually made from organic-inorganic hybrid materials such as polycarbonate. However, the current cost is relatively high, and commercial production is still difficult to popularize.

In addition to the photoelectric conversion efficiency, the choice of solar panels should also be combined with the market price of these street lights. Crystalline silicon solar panels are often our top choice. But on cloudy days, that tends to be less effective. If your sales market is in an area like London where there are more rainy days all year, other materials may be the best choice. In contrast, thin-film solar panels are almost unaffected by charging in low-light environments. If you want to sell solar street lights in London, you can include thin-film solar panels in your range of options. Therefore, when choosing solar panels, buyers should comprehensively consider the market, climate, budget, voltage resistance, etc.

The capacity of the battery determines whether or not a solar street lamp can ensure stable lighting. The capacity and life of the battery directly affect the working of the lamp. This is especially true in areas with long periods of cloudy weather and limited sunlight. Examples include London (about 1,460 hours of sunshine per year on average) or Seattle (about 2,170 hours of sunshine per year). By using solar street lights in these areas, the demand for batteries will increase.

Let's dig into some of the details. Usually, the battery capacity of the street lamp is combined with the wattage of the lamp bead to calculate the voltage needed to power the lamp. If a 60-watt solar street lamp normally works for 6 hours a day, the daily power consumption is 360WH. If you want to ensure you get three consecutive rainy days, you need to be equipped with 1080WH of electricity. We then divide the three days' power by the battery's voltage to get the battery's capacity. For example, we use 11.1V ternary lithium batteries with a capacity of 1080/11.1≈97.2AH. In a cloudy area like London or Seattle, if you're going to achieve the same 6 hours of lighting, you may need to account for longer rainy days to configure the batteries. We compensated for the reduction in solar absorption by increasing the capacity of the battery, ensuring stable lighting on cloudy days.

Now let's talk about battery material. The commonly used battery types in solar street lamp systems include lead-acid batteries, lithium-ion batteries, nickel-cadmium batteries, and other battery types. The most commonly used batteries on the market are lithium-ion batteries that are powered by a single battery. Lead-acid batteries have a short cycle life, usually between 200 and 300 cycles. And because of its heavy weight, it usually needs to be replaced when its life runs out. Nickel-chromium battery cycle life is between 700-1000 times. It has a lower price and a longer cycle life, but it is not environmentally friendly. Among them are lithium-ion batteries (divided into: lithium iron phosphate batteries, lithium manganese acid batteries, ternary lithium batteries, and other conventional batteries). I'm going to show you two of the most common ones. Lithium-iron phosphate batteries are more common, and their cycle life can reach 2000 times. Then there is the ternary lithium battery, which is characterized by its high capacity and small size. The cycle life of a ternary lithium battery is 500–1000 times longer. Some high-power solar street lights are often configured with terpolymer lithium batteries because they can compress a certain volume while meeting high capacity. Batteries with a longer life cycle reduce the need for frequent replacement, ensuring cost savings in the long run.

The lamp bead is the core component of the solar street lamp, which directly determines the performance of the lamp. The life of the lamp bead largely determines the life of the entire solar street lamp. High-quality LED lamp beads have better heat dissipation and brightness than ordinary lamp beads. Philips, Osram, Corey, and NICHIA are very good lamp bead brands. Brand owners and engineers often require the use of these brands of lamp beads when purchasing. Such buyers tend to purchase higher-quality solar street lights and more efficient lighting systems.

For those targeting the wholesale and retail markets, there are cost-effective alternatives. The Chinese-made 5730 LED chips are a popular choice, offering a commendable luminous efficiency of 120 lm/W. With a lifespan spanning 30,000 to 50,000 hours, they present a more budget-friendly option without compromising too much on quality.

| Lamp bead specifications | Luminous Efficiency | Features |

|---|---|---|

| 2835 LED Chip | 150lm/W | Suitable for projects requiring high lumen output, good efficacy, and reliability |

| 3030 LED Chip | 130lm/W | 3030 chips, primarily used in street lights and floodlights |

| 5050 LED Chip | 150-160lm/W | Large surface area and strong heat dissipation, suitable for long-term use in harsh outdoor environments |

For road projects, it is recommended to use branded LED chips if you purchase solar street lights. This provides high luminous efficiency and a longer lifespan. Buyers will need to combine their own sales goals and budgets to choose an LED chip. If you want to minimize maintenance and replacement costs, the best option is to use branded light beads.

IP rating is one of the indicators used to evaluate the resistance of solar street lights to bad weather. It determines whether a lamp can protect a working part from water, dust, or solid objects. A higher IP rating means better maintenance of electrical safety and a longer service life of the product. The first digit in the IP rating represents the level of protection against solid objects. The second digit in the IP scale represents the level of protection against pure water (from 1 mm of rainfall to temporary immersion up to 1m).

Take IP65 as an example: "6" means dust prevention, and "5" means water injection from any angle. The IP65 test requires a pressure of 30 kPa, a distance of 3m, and a water volume of 12.5L/min. Testing times are 1 minute per square meter. For most outdoor lighting, IP65 is fine.

Some rainy areas require an IP66, with a "6" meaning it can withstand powerful water jets and rough seas. The IP66 test requires a pressure of 100 kPa, a distance of 3m, and a water volume of 100 L/min. Test duration: 1 minute per square meter, 3 minutes per square meter.

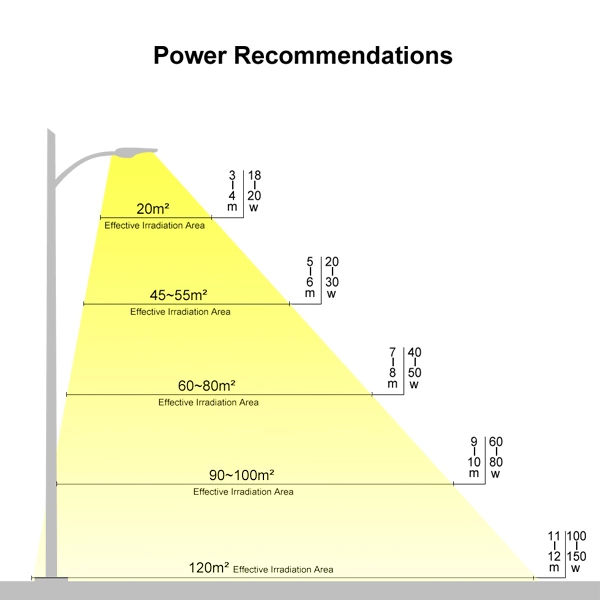

The pole height of a solar street lamp is between 3-7m. Here, we focus on the common light pole material. There are many kinds of light pole materials on the market: iron, aluminum alloy, galvanized steel, and more. Each material has its own unique advantages and considerations.

Iron light pole

Iron light poles are the most widely used light pole material on the market. Iron light poles are cheap, but they can be heavy as well. The anti-rust process is typically used to first galvanize the welded lamp pole and then spray paint, which has a double protection effect. The service life of an iron light pole is about 5 to 8 years. Service life is relatively close to that of the solar street lights. When the supplier's anti-rust process meets those standards, iron light poles are the first choice for traders.

Galvanized steel light pole

Galvanized steel poles are known for their rust and corrosion resistance and are usually treated with hot-dip galvanizing. This treatment complies with international standards and ensures that the poles are resistant to environmental factors. With this protective layer, the galvanized steel rod has a service life of up to 15 years. Galvanized steel pipe is lighter than regular steel pipe, but it is also more expensive. It is generally used for street lights in engineering projects.

Aluminum alloy light pole

Aluminum alloy light poles are better for durability and beauty. These rods are made of high-strength aluminum alloy and are themselves resistant to corrosion for more than 50 years without any surface treatment. Its cost is about six times that of iron street lamps, and there are more exports to developed countries. It is commonly applied to yard lights in some parks and is an excellent choice for projects that focus on functionality and visual appeal.

In short, the selection of light pole materials should be consistent with the project's goals, budget, and life expectancy. Whether it's the economy of iron or the lasting beauty of aluminum alloys, each material has unique advantages to meet different project needs.

Solar street lights often design other functions on the basis of using solar power to achieve more efficient energy savings. Almost all solar street lights on the market are customized with multiple gears to achieve high efficiency and energy savings. Most solar street lights achieve energy savings by customizing multiple brightness modes or sensing functions. Tailoring these specific features to your marketing or project uniqueness can further save energy. This ensures the best performance from street lights without unnecessary power consumption.

The first common strategy is to customize the lighting duration and brightness levels to suit your needs. For example, in the evening, when there is a lot of pedestrian traffic, the first 3 hours are set to 100% brightness. As night approaches and activity decreases, the brightness gradually drops to 60% over the next 3 hours. The final function is controlled by the remote control. This not only saves energy but also extends the service life of LED chips.

The second approach involves installing integrated sensors. These sensors detect movement in the vicinity of a street light. When activity is sensed, the light ramps up to 100% brightness, ensuring safety and visibility. In the absence of movement, the brightness is reduced, conserving energy while maintaining a constant brightness. This adaptive lighting approach is especially beneficial in areas with sporadic nighttime activity, ensuring that the lights are at full brightness only when necessary.

Here are just two common energy-saving solutions on the market, and you can even combine the two to customize multiple gears. Of course, if you want to be more energy efficient, some manufacturers can also offer customized energy-saving solutions. This can be combined with different budgets to make decisions.

Which provider you choose depends on where you are and how much you want to spend. Due to the rapid development of the lighting industry, the number of manufacturers has also increased sharply. This evolution complicates the task of choosing a quality LED lamp manufacturer. The following points will help you choose the right LED street lamp manufacturer:

When your project is likely to involve long-term collaboration, an evaluation of the production line is necessary. For example, you can inspect an assembly line to assess production capacity and check burn-in test equipment, IES test equipment, and IP test equipment to evaluate quality control.

Suppliers should have at least 5 years of manufacturing experience and a number of successful projects. These experiences and examples can help you refer to the results of your projects.

LED street lamp manufacturers have a wealth of knowledge about the use of LED lights. Learn how to design LED street lights for your projects. They must understand the new age of lighting and be prepared to do the same. They have advanced equipment to keep up with the latest trends in LED lighting. This is in order to provide a seamless lighting system for a street light project.

If you are looking for cost-effective and high-quality solar street lights, then you should definitely look at China. Thanks to the excellent LED industry chain, Chinese manufacturers can quickly design and manufacture solar street lights and have a large capacity for the production of solar street lights.

YINGHAO has introduced an exciting addition to the realm of solar street lighting: YH0103, YH0104, and YH0105. Our latest street light series showcases an integrated design that sets it apart from the rest. By combining monocrystalline silicon solar panels with a plate and shell design, these street lights efficiently utilize space and charge more efficiently. Don't miss the opportunity to partner with Yinghao to create a sustainable future. Contact us now to explore our latest offerings and embark on a greener path for your business. Make the right choice and illuminate a brighter, eco-friendly future with Yinghao's cutting-edge solar street lights.

As urban planning continues to rapidly develop, the application of solar street lights is becoming more and more popular. This comprehensive guide serves as a guide for B2B traders on how to choose the right solar street light for your business. From the introduction of the various components of the solar street lamp to its maintenance recommendations, a holistic view is provided here. It is also important to include the point of evaluating suppliers to ensure that the street lights you buy are of reliable quality or for after-sales. Businesses are urged to consider not only their costs but also their sustainability and energy efficiency. By prioritizing these aspects in your projects, businesses can pave the way for a brighter, greener future.

We are available from Monday to Friday

8:30-18:00

YINGHAO

Street: Liande 69

City: Guangdong Province, Zhongshan

ZIP code: 528414

Country: China

This website uses anonymous performance cookies to ensure you get the best experience on our website. We never use targeting or advertising cookies.

Please click here to view our cookie policy.